V-notch, chasing cracks and joints

What is meant by V-notch or “chasing” a crack and how is it done? Cracks, expansion joints, divots look unsightly, they trap dirt and spills making it difficult to maintain the epoxy coated floor and keep it looking sharp and clean. They may also absorb epoxy coatings robbing precious material from your floor’s surface resulting in a thinner coat than anticipated. Large expansion joints also make it difficult to roll castered carts, tool boxes, floor jacks etc. Fortunately, we have a variety of products to fill these voids. For high performance crack and joint filling, we recommend Wolverine Coatings’ IntegraFlex 1921 Flexible Joint Sealant.

For a small “hairline” cracks it is fine to just fill with IntegraFlex 1921, however for larger concrete cracks or joints take the time to first form a “V-notch” in the crack – this is commonly referred to as “chasing the crack”. Here is why chasing the crack is important.

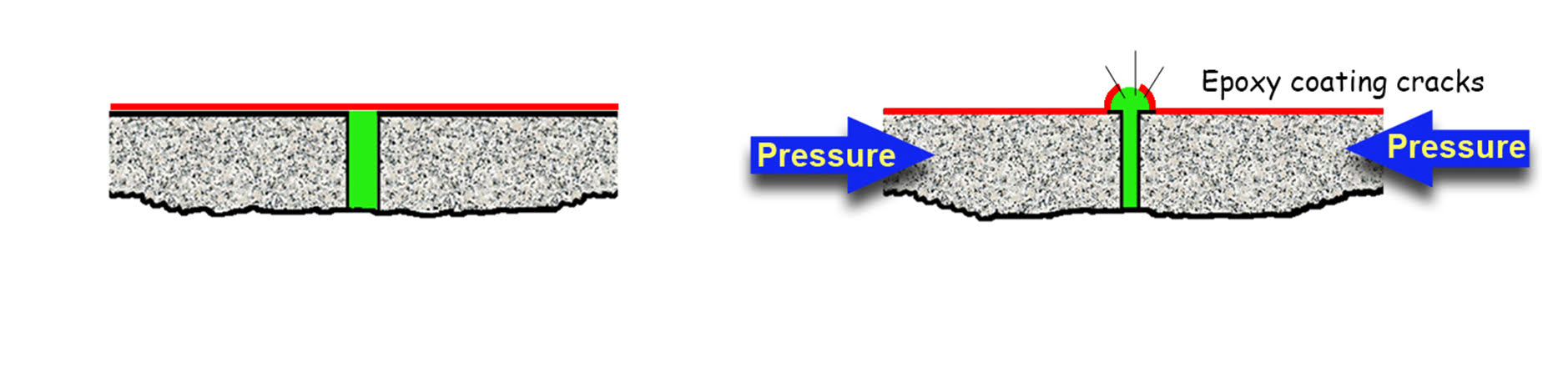

After a crack or expansion cut is filled with IntegraFlex 1921, or any other putty, as the concrete expands or shifts it may compress the putty and squeeze it up and out of the crack. If too much material is forced up it may cause the coating to split on the surface.

One way to help prevent this is to cut or grind a “V-notch” along the length of the crack or joint before the filler is applied. The notch spreads out the pressure and helps minimize the chance of the epoxy coats splitting.

There are several tools available to chase the crack. Probably the most common DIY method is to use a hand held angle grinder. A diamond cup wheel attached to an angle grinder and applied at an angle along the edges of the crack will do the job nicely. Be sure to check with the tool manufacturer’s usage recommendation and always wear proper personal safety equipment.

Note that the larger the crack, and the more filler used, the greater the potential for displacement and problems. So, if the floor has a deep “bottomless” crack rather than attempting to fill the void completely with filler you should first stuff some foam “backer rod” (available at any quality hardware store) in the crack before filling with IntegraFlex 1921. The backer rod should be about 1.25x larger than the crack to be filled. It will compress when inserted. Backer rod is also highly recommended for expansion joints as it will isolate the bottom of the joint from adhesion with the IntegraFlex. In this manner the IntegraFlex bonds with both vertical surfaces but remains free from the bottom horizontal surface so when the concrete moves the chances of the flexible IntegraFlex shearing are greatly reduced.

IntegraFlex 1921 is 100% solids, two component polymer hybrid resilient filler for expansion joints and cracks in concrete or masonry. When cured IntegraFlex 1921 is extremely durable yet retains excellent flexibility (up to 50% elongation at 70°f), it is self-priming, and provides exceptional adhesion characteristics. IntegraFlex 1921 is recommended for expansion joints in general industry as well as expansion joints in garages, highways, bridges, concrete flatwork and marine decks. IntegraFlex 1921 provides excellent bonding surface for other Wolverine Coatings Corporation products like BondTite 1101.

For repair of damaged concrete see “Concrete Repair – TrowelEase 1162”

For Application Instructions for IntegraFlex 1921 see “Filling Cracks and Expansion Joints – TechNote “